for Seamless join corner 45 degree edges

|  |

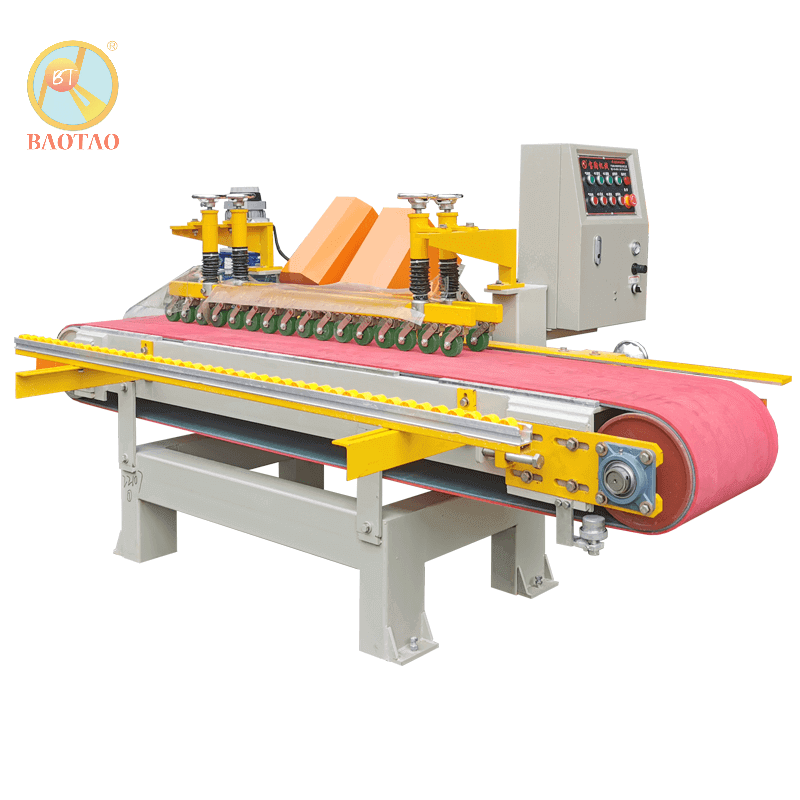

| 3 head 45 degree machine | finished product |

This machine has 3 heads,

-the first motor is for cutting 45 degree edge with miter circular saw blades, -while the second motor is for trimming or rectify the chipping of glazed surface edge with resin grinding wheel,

-the third grinding wheel for making the edge to be sharp and seamless,

-in this way we can glue the corner without any manually grinding.

Consumables and Tools for machine:

Diamond cup-shape grinding wheel x1

260 mitering circular blade x1

Snail lock resin chamfering block x1

Machine Parameters:

| Technical Parameter | Unit | BT1800-3H auto 45 cu machine |

| Conveyor belt width | mm | 400 |

| Working heads | Cutting + grinding + cleaning | |

| Diameter of cutting blades | mm | 260 |

| Diameter of chamfer wheel | mm | 150 |

| Diameter of cleaning wheel | mm | 100 |

| Processing thickness | mm | max 20mm |

| Processing size | mm | 50~180 |

| Total power | kw | 3+3+0.75+0.75=7.5 |

| Dimension(LxWxH) | meter | 2.4×1.2×1.4 |

| Processing speed | m/min | 0.8-2 |

|  |

| 1.automatic cleaning heads and adjustable cutting heads, for different thickness tiles | 2.easy operation system with foreign language |

Finished products:

|  |

| Stair treads of ceramic tiles | Sintered stone wash basin |

Machine Application:

|  |

| Ceramic Cutting Factory | stone processing company |

Machine real photo shoots:

Machine Packing and Shipping:

|  |

| bare packing with protection films, by full container loading | wood box packing, by LCL consolidation |