A porcelain tile processing workshop can do all kinds of workings of tiles, like cutting, 45 angle miter, stair step tile manufacturing, skirting tiles, window sill, wall tiles, water jet medallion flooring. Some workshops offer more service like paving and installation of tiles, or construction.

↑round edge / ¼ bullnose

↑ 45°angle miter edge

↑carpet medallion tiles

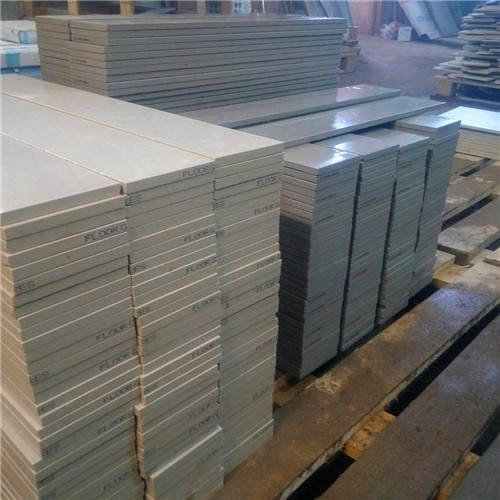

↑ strip tiles, mosaic tiles, plinth baseboard

↑ stair step nosing tiles with anti slip groovings

Let's see some successful project cases firstly:

What you need to prepare?

to open a fabrication workshop for ceramic tiles processing/manufacturing?

# Find a place of 100-500 square meters.

# electricity of industrial power supply, normally 380V, 415V.

# 30-50 kw electric power supply.

# Copper electric cable of 16 square or above.

# water tank recycling of 5-7 cubic meter(CBM).

# air compressor with 2.2KW and 8KG pressure.

# water pump 1.5kw.

3 porcelain tile processing equipments you may need:

1. Arc edge machine to make stair cascade tiles, skirting tiles.

2. Auto Front and back blade cutting machine

3. Multi function Manual cutting profile machine

Please contact for more details, we have professional export team to support your business.