The stone infrared bridge cutting machine, especially when cutting marble cabinets and opening basin holes, demonstrates its high precision and high efficiency. The following is a detailed introduction to the three-axis CNC stone infrared bridge cutting machine:

Equipment Overview:

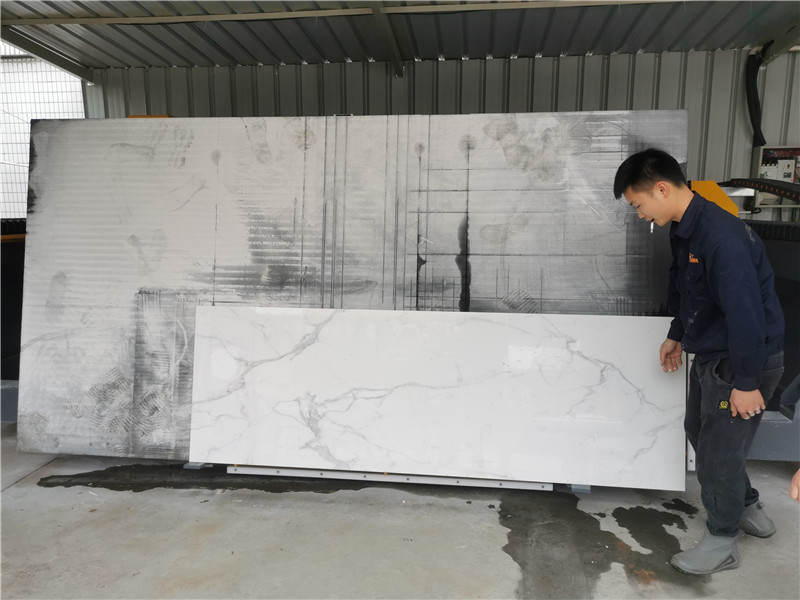

Infrared bridge cutting machine, also known as infrared automatic bridge cutting machine, is a high-precision and high-efficiency stone cutting equipment.

It uses infrared technology for knife alignment, ensuring extremely high accuracy in the size and straightness of the cut stone.The three-axis CNC type means that the equipment has CNC functions in the X, Y, and Z directions, enabling complex and accurate cutting operations.

Cutting marble cabinets:

The infrared bridge cutting machine can accurately cut marble cabinet panels according to the predetermined size and shape.The automation control system makes operation simple, and the equipment can automatically complete cutting by inputting the required size.High precision cutting ensures the flatness and dimensional consistency of cabinet panels, improving the overall quality of the product.

Opening basin hole cutting:

The three-axis CNC infrared bridge cutting machine can easily handle complex hole opening requirements, such as pot hole cutting.

Through precise programming and positioning, the device can accurately cut holes of various shapes and sizes.This high-precision cutting reduces the demand for subsequent processing, improves production efficiency and product accuracy.